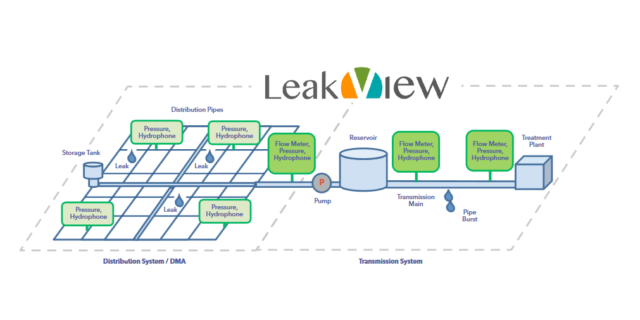

LeakView™ is an advanced sensing platform for real-time detection of pipe breakages. The system comprises multiple pipe leakage indicators, such as high-rate (64-256 samples/sec) pressure sensors, hydrophones and flow meters installed at optimal locations – coupled with minute-by-minute data analytics for anomaly detection.

The sensors transmit continuous information about the condition of the pipe network to a cloud-based data management and analytics engine. The LeakView™ system identifies the pressure transients generated by potential pipe breakage and localizes the event to the faulty pipe with high likelihood. This detection process is automated and provides information on the severity of leaks to help the repair crews prioritise their response.

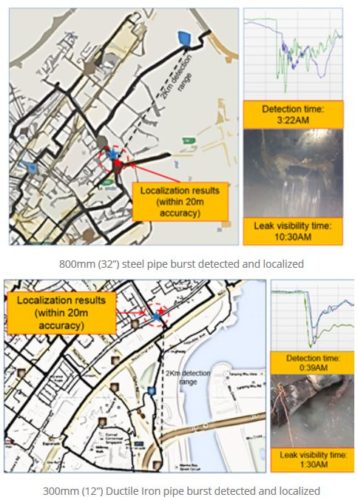

Singapore’s national water supply agency, PUB, has implemented Visenti’s pressure monitoring and leakage localization tools in the complex pipe network of downtown Singapore. This CBD network comprises 300 km of pipes spread around an area of 60 ㎢ and delivers 40 MLD of potable water to approximately 0.5 million customers.

Singapore’s national water supply agency, PUB, has implemented Visenti’s pressure monitoring and leakage localization tools in the complex pipe network of downtown Singapore. This CBD network comprises 300 km of pipes spread around an area of 60 ㎢ and delivers 40 MLD of potable water to approximately 0.5 million customers.